-

Par alvarad982stedk le 9 Avril 2020 à 10:02

China plastic injection molding manufacturer

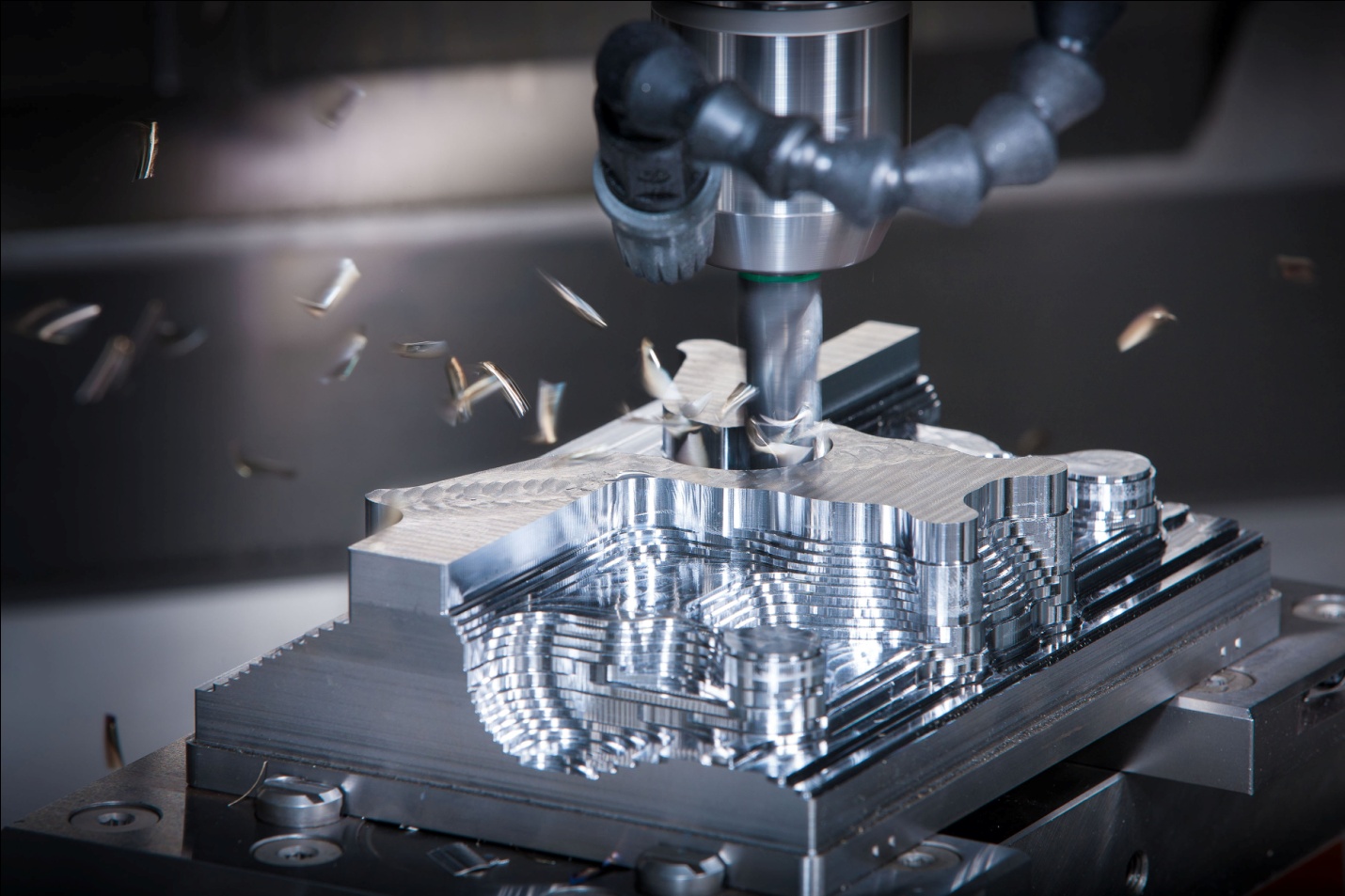

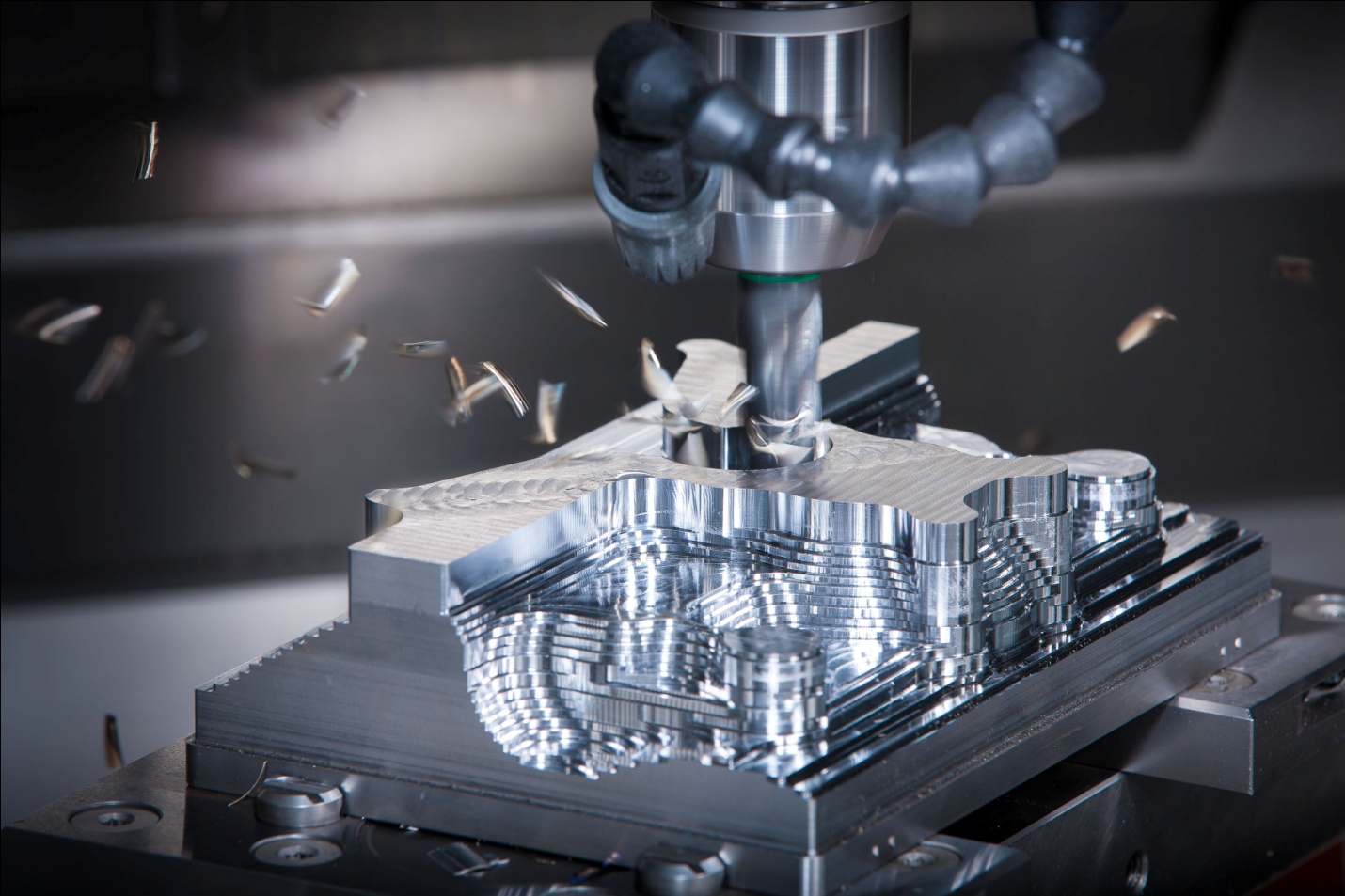

Abbreviated as Computer Numerical Control, CNC machining is basically the automation of machine equipment using computers giving out pre-programmed sequences and features of machine control commands. The manufacturing industry, today, relies heavily on CNC machines as they replace certain crucial operations that once needed engineer operated tools for the working, such as routers, shaping machines, vertical millers and so on. Manufacturers all across the globe seek help from CNC machining services to avail of the amazing benefits of CNC machining for their manufacturing and fabrication applications.

There are some great advantages of using CNC machines as compared to other conventional forms of production and manufacturing. The following are just a few of the major ones.

1. CNC Machining processes save on the entire manufacturing and Production Cost:

By using CNC machines, you can take full advantage of all the raw materials involved in the process as the machines can operate accurately and significantly and reduce a good amount of waste. Furthermore, this helps the machine operator reduce any loss that they may incur thereby, enhancing great profitability in the long run.

2. It produces the exact result every single time when used:

Another big benefit of using CNC machining is that it offers exact results every single time when used for production or manufacturing. It’s obvious that even the best human worker will make minor issues and differences between the two finished results. However, a CNC machine will produce exactly the same result every time when it is operated.

3. It offers Labor Safety:

CNC machining saves lives. The worker operating the machine is safely separated from all the tools and devices by a special protective construction. He sees what all is going on in the machine tool through clear glass and doesn’t need to go near the spindle or mill.

4. CNC Machines are Flexible:

While there’s no doubt that humans are more trained and flexible than machines, CNC machining can be completely reprogrammed anytime when needed. With a CNC machine, it is possible to refer back to previous programs and install new ones when a different work piece is demanded. This feature, however, gives a big benefit over other traditional machines, since they can easily shift to producing or manufacturing a completely different piece of product that too without the need of installing new parts or components.

Free shipping coupon code: "freeshipping" on any order from yiannopoulos.net

5. It increases the speed of the Entire Manufacturing Process:

CNC machining is an incredibly efficient process, and due to this, the manufacturing process cuts down on several steps that it takes to manufacture a specific part. Thus, you can create multiple parts in much shorter duration as compared to using other manufacturing processes.

So, as you can see there are a whole lot of advantages of using CNC machines and it is very clear that these machines are an extraordinary way of manufacturing a different variety of items. While other conventional manufacturing machines have their own benefits, the advantages of using CNC machining services tend to outweigh any differences because of how adequate and productive they are.

votre commentaire

votre commentaire

-

Par alvarad982stedk le 7 Avril 2020 à 13:52

China plastic injection molding manufacturer

Abbreviated as Computer Numerical Control, CNC machining is basically the automation of machine equipment using computers giving out pre-programmed sequences and features of machine control commands. The manufacturing industry, today, relies heavily on CNC machines as they replace certain crucial operations that once needed engineer operated tools for the working, such as routers, shaping machines, vertical millers and so on. Manufacturers all across the globe seek help from CNC machining services to avail of the amazing benefits of CNC machining for their manufacturing and fabrication applications.

There are some great advantages of using CNC machines as compared to other conventional forms of production and manufacturing. The following are just a few of the major ones.

1. CNC Machining processes save on the entire manufacturing and Production Cost:

By using CNC machines, you can take full advantage of all the raw materials involved in the process as the machines can operate accurately and significantly and reduce a good amount of waste. Furthermore, this helps the machine operator reduce any loss that they may incur thereby, enhancing great profitability in the long run.

2. It produces the exact result every single time when used:

Another big benefit of using CNC machining is that it offers exact results every single time when used for production or manufacturing. It’s obvious that even the best human worker will make minor issues and differences between the two finished results. However, a CNC machine will produce exactly the same result every time when it is operated.

Free shipping coupon code: "freeshipping" on any order from yiannopoulos.net

3. It offers Labor Safety:

CNC machining saves lives. The worker operating the machine is safely separated from all the tools and devices by a special protective construction. He sees what all is going on in the machine tool through clear glass and doesn’t need to go near the spindle or mill.

4. CNC Machines are Flexible:

While there’s no doubt that humans are more trained and flexible than machines, CNC machining can be completely reprogrammed anytime when needed. With a CNC machine, it is possible to refer back to previous programs and install new ones when a different work piece is demanded. This feature, however, gives a big benefit over other traditional machines, since they can easily shift to producing or manufacturing a completely different piece of product that too without the need of installing new parts or components.

5. It increases the speed of the Entire Manufacturing Process:

CNC machining is an incredibly efficient process, and due to this, the manufacturing process cuts down on several steps that it takes to manufacture a specific part. Thus, you can create multiple parts in much shorter duration as compared to using other manufacturing processes.

So, as you can see there are a whole lot of advantages of using CNC machines and it is very clear that these machines are an extraordinary way of manufacturing a different variety of items. While other conventional manufacturing machines have their own benefits, the advantages of using CNC machining services tend to outweigh any differences because of how adequate and productive they are.

votre commentaire

votre commentaire

-

Par alvarad982stedk le 7 Avril 2020 à 13:00

What is injection molding?

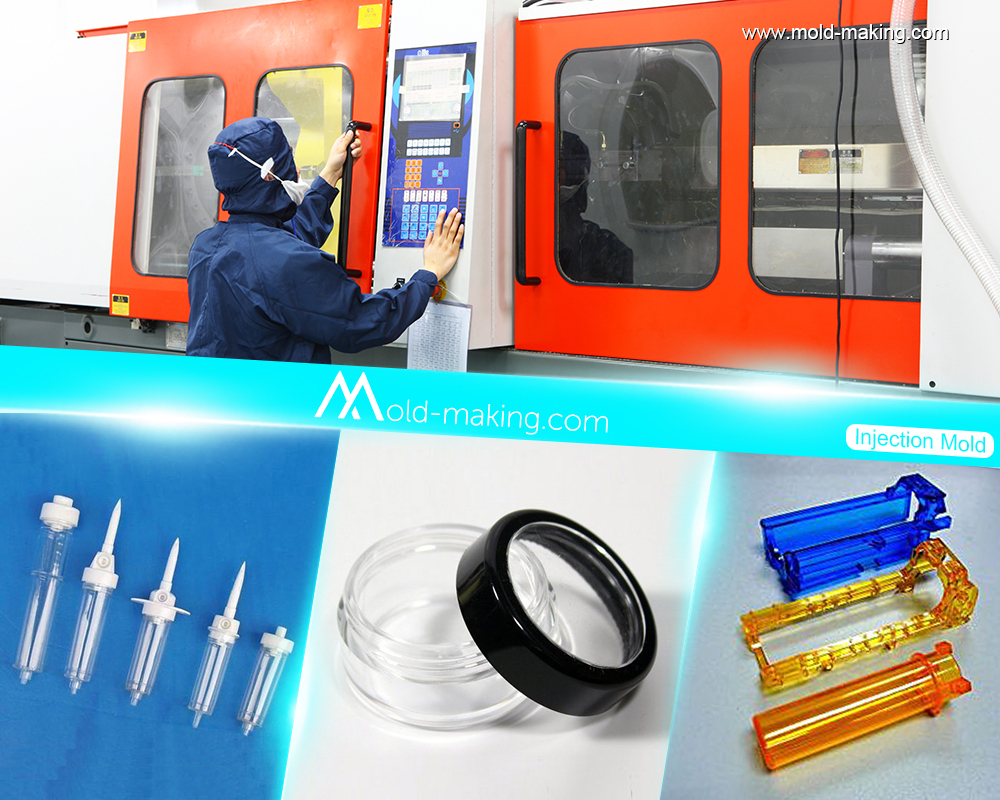

Injection molding is a manufacturing process commonly used for fabricating items from plastic trinkets and toys to automotive body parts, cell phone cases, water bottles, and containers. Essentially many of the plastic parts that we use in every-day life are injection molded. It is a quick process to create a mass amount of identical plastic parts. The flexibility in shape and size achievable by the use of injection molding has consistently widened the boundaries of design in plastics and allowed substantial alternatives of traditional materials due to design freedom and light weighting.

The plastic injection molding is a most common process to produce a large volume of plastic parts which has been finished for commercial and for the industrial use. In molding process, the molten resin is being injected under a very high pressure in a metal device. After this process it is being cooled and forms a perfect shape. Only single phase required making this finished part completely and it will take few minutes depending on its complexity and the size of the metal to be molded.

mold making china

mold making china

Importance of the existence of mold manufacturers in China

In China there is a great demand for multiple products, so all manufacturers must make a great effort to meet everyone’s needs, without exceptions.

China is a country that has been characterized by always being at the forefront, and it is that it has a great responsibility to meet the needs of all the inhabitants of its various regions, thus providing a large number of products that reach all citizens.

No factory is exempt from this huge commitment, so they always make sure they bring only the best to their customers. Of course within this group you can easily find a China mold factory, since its presence is quite required by multiple customers who require their services.

Free shipping coupon code: freeshipping on any order from mold-making.com

Even the mold factories in China have this great responsibility, so they strive to offer only the best products and the best quality for all.

A China mold Factory has the duty to create not only quality products, but also these will have to meet all the demands and requests of its customers who sometimes look for a particular product, and not something that has already been arranged in some stores.

Creating is the main task of a China plastic injection molding manufacturer, since it knows that repeatedly, customers also present their proposals for products they wish to materialize, and these mostly have unusual structures, which means that a standard mold may not be enough to achieve this task.

Usually, a China plastic injection molding manufacturer must not only create standard products, but also some customized ones, in order to reach more people.

A China plastic injection molding manufacturer that creates custom molds, carries with it the responsibility to succeed in the structure of all the products they will create from their work. The existence of a Chinese plastic injection molding manufacturer or several, makes all the manufacturers that depend on these products and the raw material they can offer them, can be quite creative, since from these models they can get free rein to all its models and designs, being these more and more creative than its first versions.

Having a China mold Factory that has real knowledge of how to manufacture these products is undoubtedly one of the greatest advantages that can be had today. When you are a manufacturer of certain products, you always take into account how easy or difficult it will be for you to find the raw material, but in the case of a mold maker the most important thing is to keep in mind that customer requests can be different every day.

How to find a good mold maker in China?

There are lots of different standard mold makers in China. The most important and difficult thing is to choose the right mold maker for a company at the beginning. Sometimes it takes a long time. Although it’s kind of easy to find a well-known mold shop in UK, Germany, US and Japan, but to find a good mold maker in China with reasonable price is really not as difficult as you think was. You should know something about the Chinese mold market, where are for low prices where are for low quality… 1st of everything you’d better to know what do you really want from the mold maker with your prices. To attend mold trial is kind of a right thing, a suggestion you may also follow is requesting sampling video for each trial to save your time and traveling cost. Of course there are some exceptional for some very complicated and super big molds, in the other meaning for some very expensive molds.

The important thing is you need to select the proper mold maker in China and review terms and conditions in your quote as well as warranty clauses. Mold quality is improving these days but you still need to supervise the mold design and qualification of your tool to make sure you received what you paid for.

One of our customers took the designs from a complicated mold that designed by their local mold designer and ask us to build for them due to the expensive cost in local mold manufacturing. They contracted with Wing Tat mold makers to build another mold based on the design. The mold has been running for 14 years without any trouble.

It takes times to find good suppliers and build the partnership, not only in China, but all over the world. The expectation and understanding would be very important for the success, the companies should try to build partnership with their suppliers if they got the best one, that would be very helpful for your mold supplier understood your requirements and expectations.

Requests can vary greatly, especially if they are orders that need to be fully customized, that is, they require specific instructions to be able to execute successfully. In this way, customers and users of these mold companies can take their ideas far beyond what they expected because they no longer feel limited in their structure. This is how we gradually see how the market in various fields can grow without stopping.

For more about mold manufacturers in China,you can pay a visit to Mold-Making at https://www.mold-making.com

votre commentaire

votre commentaire

-

Par alvarad982stedk le 25 Mars 2020 à 10:23

What is Plastic injection molding?

Plastic injection molding is a very innovative process that has created many useful products that we use every day in our homes. While the history of plastic molding is full of creativity and innovation, the future is full of possibilities, something that the Chinese plastic injection molding Company are aware of, allowing them to grow even more as more creative minds add new forms to improve the process and injection molding machines.

While improvements in plastic injection machinery continue, the future of injection molding is now turning its attention to molds and mold components. High-tech plastic molds can be made of metal, epoxy or carbon fiber and can increase production through cooling times and faster cycles.

The invention of 3D printing gives us an idea of how far plastic injection molding can travel to the future. 3D printing is a process of creating a solid three-dimensional object of virtually any shape from a digital model. With the integration of 3D printing into the plastic injection molding process, concepts and samples can be produced with much less expense. This is currently taken into account by several china plastic injection molding manufacturers.

Some innovative minds have even been working with corn seed producers to replace

mold making china

mold making china

traditional petroleum-based plastic in corn-starch-based plastic. Biodegradable material is currently used on a limited scale and there are many uses that this material could soon have that would surprise the mind.All it would take would be the mold and the material to produce a new wave of the future for plastics engineering. Scientists are still investigating other polymers in the way they did when plastic injection molding began and their research is incredible at this time with many possibilities to come.

How to find a good mold maker in China?

There are lots of different standard mold makers in China. The most important and difficult thing is to choose the right mold maker for a company at the beginning. Sometimes it takes a long time. Although it’s kind of easy to find a well-known mold shop in UK, Germany, US and Japan, but to find a good mold maker in China with reasonable price is really not as difficult as you think was. You should know something about the Chinese mold market, where are for low prices where are for low quality… 1st of everything you’d better to know what do you really want from the mold maker with your prices. To attend mold trial is kind of a right thing, a suggestion you may also follow is requesting sampling video for each trial to save your time and traveling cost. Of course there are some exceptional for some very complicated and super big molds, in the other meaning for some very expensive molds.

Free shipping coupon code: freeshipping on any order from mold-making.com

The important thing is you need to select the proper mold maker in China and review terms and conditions in your quote as well as warranty clauses. Mold quality is improving these days but you still need to supervise the mold design and qualification of your tool to make sure you received what you paid for.

One of our customers took the designs from a complicated mold that designed by their local mold designer and ask us to build for them due to the expensive cost in local mold manufacturing. They contracted with Wing Tat mold makers to build another mold based on the design. The mold has been running for 14 years without any trouble.

It takes times to find good suppliers and build the partnership, not only in China, but all over the world. The expectation and understanding would be very important for the success, the companies should try to build partnership with their suppliers if they got the best one, that would be very helpful for your mold supplier understood your requirements and expectations.

Requests can vary greatly, especially if they are orders that need to be fully customized, that is, they require specific instructions to be able to execute successfully. In this way, customers and users of these mold companies can take their ideas far beyond what they expected because they no longer feel limited in their structure. This is how we gradually see how the market in various fields can grow without stopping.

Finally, what is this procedure?

Plastic injection molding, by definition, is the process of injecting plastic into a mold, then the plastic cools, and that is when it is ejected from the mold and the finished product is packaged for sale to the customer. This sounds simple and in its basic form is, but the process involved in making all this happen is really quite complicated. The plastic can be injected into the mold at low pressure, but it is usually made under high pressure at a cavity pressure of more than 30,000 PSI.

There are many different types of injection molding and many different types of plastic injection molding machines. Some of the types most used by the different China plastic injection molding supplier are standard mold injection, insert molding, plastic extrusion, blow molding, multicolored or material molding, stacking molding and molding rotating, to name just a few.

There are also custom plastics, from the most common plastic resins to the most exotic engineering grade resins used today in most cars. There are even quality “metals” for injection molding that are being experimented with these days.

There are many types of injection molding machines, all made for specific purposes. There are standard horizontal injection molding machines that vary in size from a few tons to 9000 tons and more. You could drive a car between the plates of such a large press.

For more about mold manufacturers in China,you can pay a visit to Mold-Making at https://www.mold-making.com

votre commentaire

votre commentaire

-

Par alvarad982stedk le 13 Décembre 2019 à 08:10

How to choose the injection mold steel reasonably is a complex project, and it is also the key link of the injection mold manufacturing. This is an important work related to the service life of the mold and the cost of the injection mold. Generally, the materials used to make plastic injection mold need to have certain hardness and wear resistance first. Secondly, it should have strength and toughness. Before choosing the injection mold steel, we need to know the classification of the mold. According to its service life, the mould is usually divided into five grades:

Level 1: the service life of the mould is more than one million times.

Level 2: the service life of the mould is 500000-1 million times.

Level 3: the service life of the mould is 300000 to 500000 times.

Level 4: die service life 100000 to 300000 times.

Grade 5: the service life of the mould is less than 100000 times.

Mingyang Yutong mould factory

In addition, the basic properties of steel need to be understood

1. The steel has enough surface hardness and wear resistance.

The surface roughness and dimensional accuracy of plastic parts and the service life of injection mold are directly related to the hardness and wear resistance of the mold surface, especially the molding surface of the mold, such as the core and cavity of the mold. Therefore, the surface of injection mold is required to have enough hardness. For small plastic mold, high carbon and high alloy steel can be selected. For large-scale plastic mould, carburizing steel can be selected and heat treated to make it harden, so as to obtain high wear resistance and prolong the service life of mould.

2. The steel has enough strength and toughness.

Because the injection mold, especially the injection mold, bears a large molding pressure in the injection process, so the large and medium-sized injection mold or the injection mold with complex cavity shape should have high strength and toughness to meet the requirements of use performance.

3. Steel has good processing performance.

Most injection molds need to perform certain machining and benchmark work. In order to prolong the service life of cutting tools, improve the cutting performance and reduce the surface roughness, the plastic injection molding steel must have appropriate hardness to obtain the necessary precision and surface roughness.

4. The deformation of heat treatment is small.

Injection mold parts are usually complex in shape, so it is difficult to process after quenching, or even impossible to process at all. Therefore, the steel with small heat treatment deformation should be selected. In this way, the processing of injection mold parts can be reduced or stopped after heat treatment, so as to ensure the dimensional accuracy and surface quality requirements of plastic mold.

5. Good corrosion resistance

Plastics and additives have chemical corrosion on the surface of steel. Therefore, the selected die steel should have certain corrosion resistance.

6. Good polishing performance

In order to obtain smooth plastic parts, the surface roughness of the cavity is required to be small, so the cavity must be polished to reduce the surface roughness of the cavity. And the selected steel will not have rough impurities and pores, and will not occur when polishing, pitting or orange peel defects

About JasonMould Industrial Company Limited

Jasonmould is a China mold maker of plastic molds- injection mold, die casting moulds, plastic blow molding, rotational molding, medical plastic injection molding, two shot plastic injection molding, insert molding, overmolding, metal injection molding, micro injection molding, powder injection molding, ceramic injection molding, liquid injection molding, husky injection molding, household mold, casting mold, die mold tool, custom molds, china moulds, rapid prototyping tooling, plastic prototyping tooling, punch press tooling, die and tooling for mobile/ cell phone parts, automotive parts, vacuum cleaners, rechargeable tools, telephones, copiers, computers, multimedia speakers, and many other electronic products and household appliances. And also a plastic product manufacturer, mold manufacturer China– plastic parts, plastic water tank, plastic balls, plastic containers, plastic buckle, plastic anchor, plastic hanger, plastic spoon, plastic pipe fitting, plastic tumble, plastic tableware, plastic cups, plastic bottles, plastic tray, plastic cosmetic container, plastic case, plastic food container, plastic chairs, plastic caps, plastic cap closure, plastic tubes, plastic water pipes, plastic knobs, plastic tubing, plastic utility boxes, plastic racks and so on.

Contact:

Person: James Yuan

Company: JasonMould Industrial Company Limited

Add: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Tel: 86-752-6682869

Email: james@jasonmolding.comSite: https://www.jasonmolding.com/custom-injection-molding/

votre commentaire

votre commentaire Suivre le flux RSS des articles de cette rubrique

Suivre le flux RSS des articles de cette rubrique Suivre le flux RSS des commentaires de cette rubrique

Suivre le flux RSS des commentaires de cette rubrique